描述

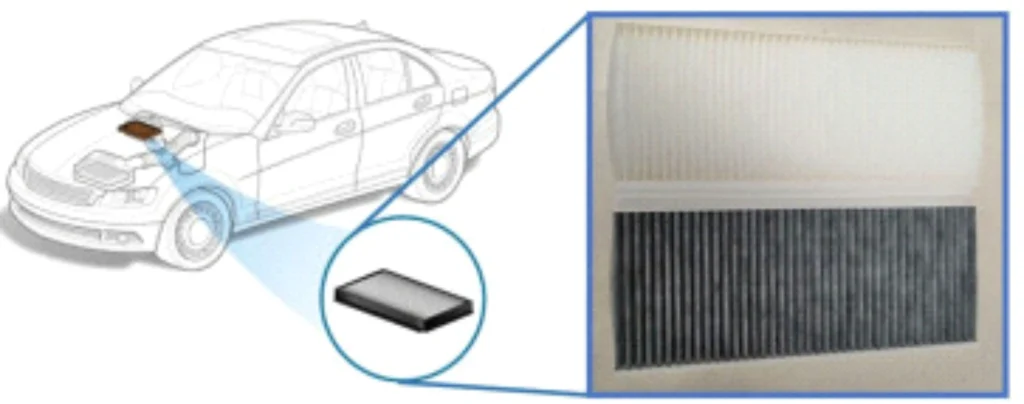

汽车空滤

活性炭在汽车空滤中的应用不仅保障了驾乘人员的健康与舒适性,更通过吸附有害气体、拦截颗粒物和微生物,成为智能汽车“健康座舱”生态系统的核心组件。

产生场景

颗粒物、尾气排放、内饰材料挥发、空调系统滋生、人为活动、新能源汽车电池舱

吸附目标物

颗粒物、挥发性有机物(VOCs)、异味气体、微生物、氟化氢(HF)、CO

应用场景

乘员舱空气净化、电池舱空气过滤、引擎进气过滤、车内异味应急处理、尾气处理

治理工艺

活性炭吸脱附、多层复合吸附、活性炭-催化氧化、活性炭-负离子净化

Clarkson产品系列

CKC-AF-TCLR, CKC-AF-CHTC

案例

某豪华品牌车载空调滤芯升级

背景:车内甲醛浓度达0.12 mg/m³(国标限值0.08 mg/m³),用户投诉异味。

工艺:采用“HEPA+蜂窝活性炭+MnO₂催化层”复合滤芯。

效果:甲醛浓度30分钟内降至0.03 mg/m³,PM2.5过滤效率99.9%。滤芯寿命延长至2年。

汽车生产制造

在汽车生产制造中,活性炭因其高效的吸附性能被广泛应用于多个环节,主要涉及环保排放控制、废气处理及车内环境优化等领域。

产生场景

喷涂工艺、烘干工序、激光焊接/电弧焊、等离子切割、注塑与热压、电解液配制、电极涂布、废水处理

目标污染物

挥发性有机物VOCs、颗粒物、重金属离子、恶臭气体、NMP、CO

应用场景

涂装车间VOCs治理、焊接烟尘净化、塑料成型废气处理、NMP溶剂回收、废水深度处理、厂区异味控制

治理工艺

固定床吸脱附、沸石转轮+活性炭、焊接烟尘协同处理、废水深度处理、NMP溶剂回收

废气→活性炭吸附→热氮气脱附(150℃)→冷凝回收NMP。

Clarkson产品系列

CKC-AM-TCLR, CKC-AM-CHTC

案例

动力电池工厂NMP回收系统

背景:电极涂布工序NMP废气(浓度8-12 g/m³),直接排放成本高。

工艺:两级活性炭吸附(蜂窝炭+颗粒炭)→热氮气脱附→冷凝提纯。

效果:NMP回收率92%,纯度99.5%