描述

养殖行业气相专用炭

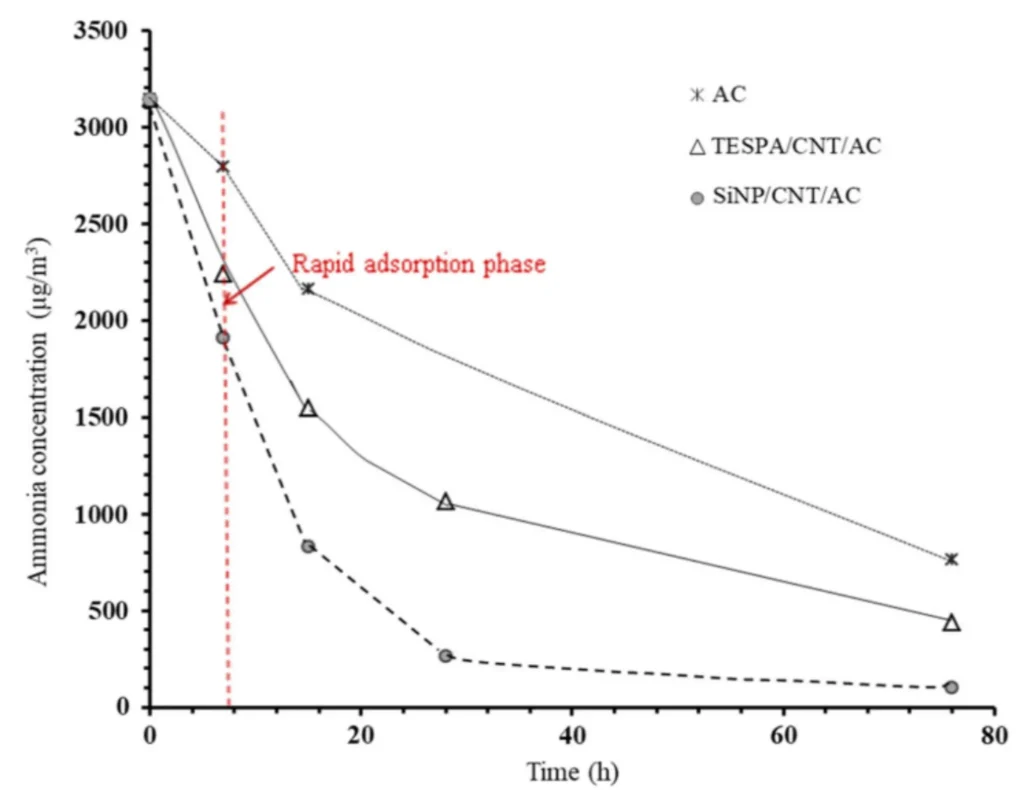

活性炭在养殖行业的气相和液相处理中发挥重要作用。气相处理方面,主要用于畜禽舍通风废气和沼气净化,通过吸附去除NH3、H2S等恶臭气体及VOCs。

产生场景

畜禽舍通风废气、粪污处理设施废气、饲料加工区废气等。

吸附目标物

H₂S CH₃SH CO₂ NH₃ CH₄ VOCs

应用场景

畜禽舍空气净化、沼气净化系统、粪污处理废气治理

治理工艺

固定床吸附

生物滤池+活性炭

化学洗涤+活性炭

Clarkson 产品系列

CKC-BR-TCLR-G,CKC-BR-CHTC-G

案例

养猪场除臭案例

应用方式:

粪便处理区吸附:某规模化养猪场在粪便堆积区上方安装活性炭滤网,通过负压通风系统将臭气吸入滤层。

垫料混合:在猪舍垫料中掺入5%-10%的活性炭粉末,利用其吸附氨气并抑制微生物产臭。

效果:氨气浓度从初始的50 ppm降至15 ppm以下,呼吸道疾病发病率降低30%。第三方检测显示,硫化氢去除率达85%,臭味强度降低70%(依据《恶臭污染物排放标准》)。

养殖行业液相专用炭

液相处理方面,应用于养殖废水深度处理,吸附COD、氨氮及残留抗生素等污染物,常用粉末活性炭应急处理或颗粒活性炭固定床工艺。

产生场景

养殖场冲洗废水、粪污处理废水、病死动物处理废水

吸附目标物

氨、重金属、磷酸盐、蛋白质絮凝物、有机物、大分子抗生素、激素

应用场景

应急处理系统、废水预处理、深度净化、循环水养殖系统

治理工艺

颗粒活性炭过滤柱、磁性活性炭回收技术、膜-活性炭工艺、活性炭吸附+臭氧氧化

Clarkson 产品系列

CKC-BR-TCLR-L,CKC-BR-CHTC-L

案例

- 江苏某家禽养殖厂:利用活性炭吸附渗滤液中Cu²⁺,浓度从15 mg/L降至0.5 mg/L。

- 某养鸭场采用“活性炭吸附+臭氧氧化”处理废水,恩诺沙星残留从50 μg/L降至1 μg/L以下。

- 挪威三文鱼养殖公司:在RAS系统中使用活性炭滤器,水体透明度提升80%,鱼病发生率降低40%。