描述

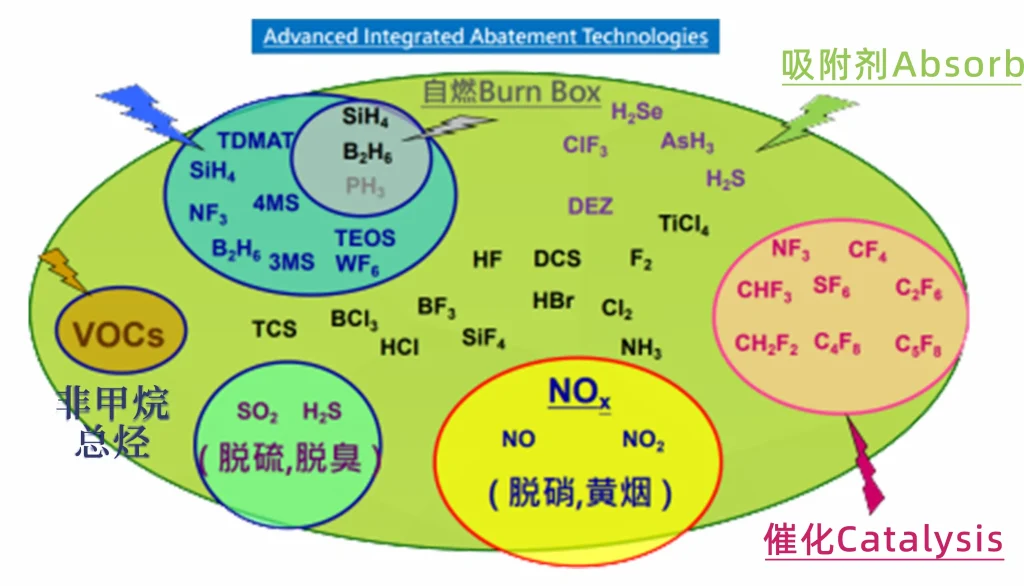

电子半导体气相专用炭

产生场景

光刻胶清洗、显影液挥发、蚀刻工艺、薄膜沉积、离子注入、CVD工艺等

吸附目标物

应用场景

洁净室空气净化、工艺尾气处理

治理工艺

多级活性炭吸附、活性炭吸附-催化燃烧(RCO/RTO)组合工艺、化学改性/催化深度处理、蒸汽/氮气吸脱附

Clarkson 产品系列

CKC-ESG-TCLR-G, CKC-ESG-CHTC-G

案例

半导体厂砷烷尾气处理

背景:某12英寸晶圆厂CVD工序排放AsH3废气(浓度50-200 ppm,风量2000 m³/h)。

技术方案:

两级吸附系统:

预处理级:改性活性炭;

深度净化级:复合吸附剂;

安全设计:吸附塔配备N2惰性保护系统,防止吸附剂自燃。

效果:

吸附剂寿命:6个月(累计处理量120 kg AsH3/m³吸附剂);

排放浓度:<0.05 ppm(严于国标GB 31573-2015的0.1 ppm限值)。

电子半导体液相专用炭

产生场景

光刻胶清洗、显影液挥发、蚀刻工艺、薄膜沉积、离子注入

吸附目标物

有机污染物、金属离子、氧化剂、VOCs、硅微粒等

应用场景

超纯水系统终端精制、化学品纯化

治理工艺

活性炭+离子交换树脂,活性炭+超滤/反渗透技术、定向高效吸附、化学改性/催化深度处理等

Clarkson 产品系列

CKC-ESG-TCLR-L, CKC-ESG-CHTC-L

案例

合肥某半导体企业将活性炭用于显影液、蚀刻液的前处理。

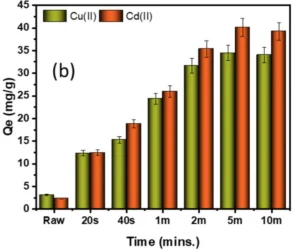

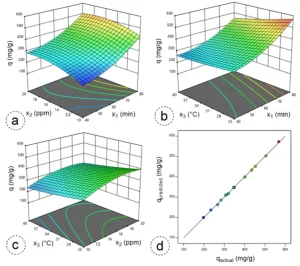

技术方案: 改性活性炭选择性吸附金属离子(Cu2+、Fe3+等)。

效果:某蚀刻液经活性炭处理后金属杂质从50 ppb降至5 ppb以下。