描述

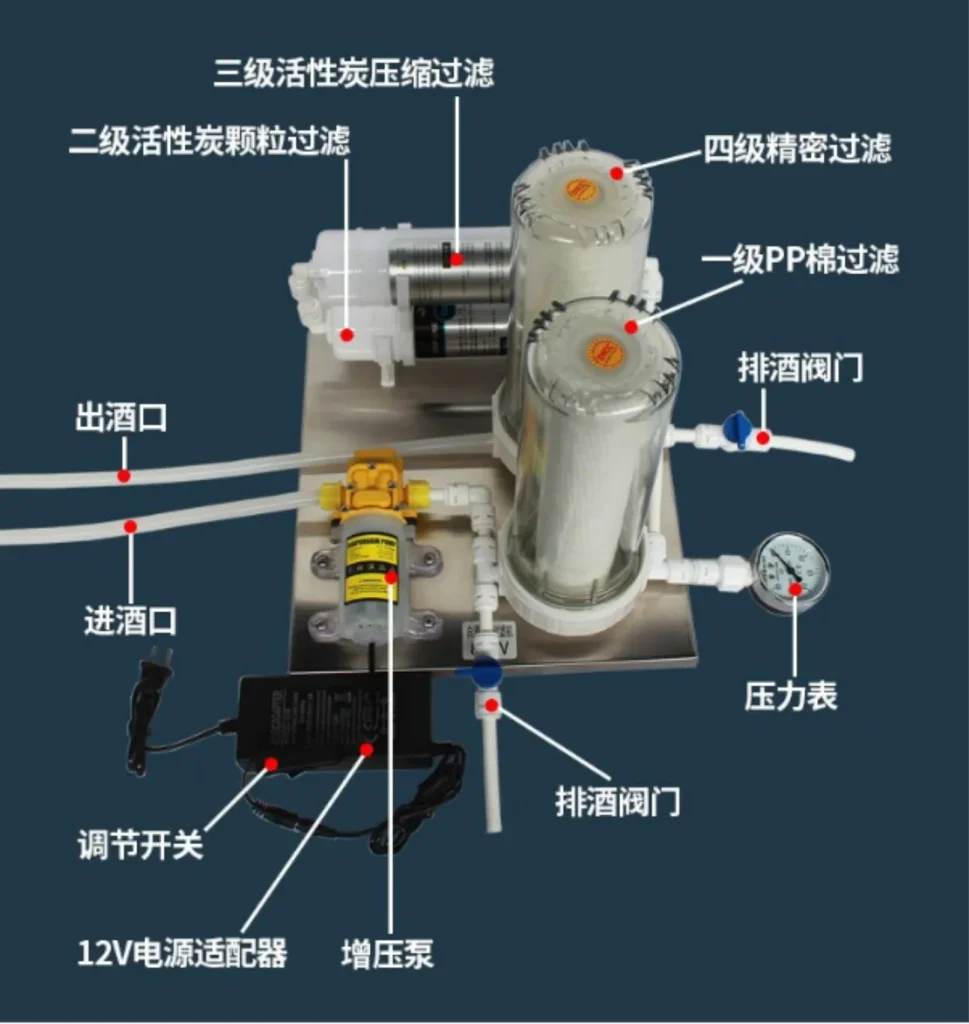

酒水饮料净化与脱色

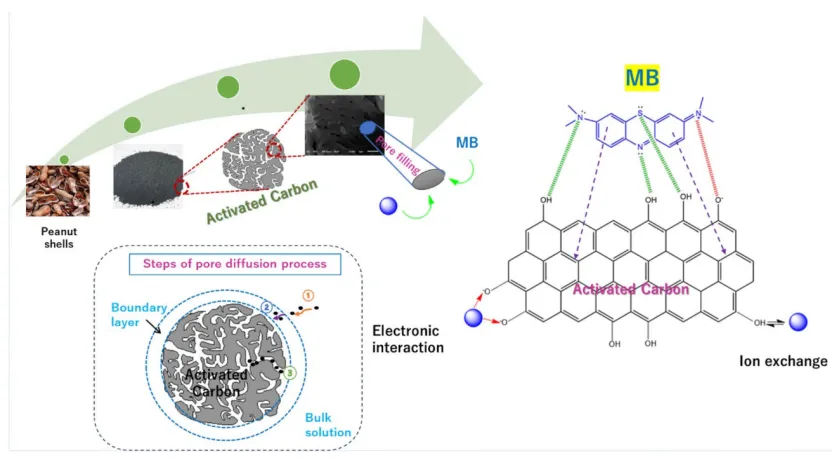

活性炭凭借其多孔结构和高比表面积,在食品饮料行业中成为净化、脱色、除异味的关键材料。其物理吸附与化学吸附协同作用,可精准去除色素、重金属、有机污染物及异味分子,同时满足食品安全与环保法规要求。

酒类在发酵与储存过程中易产生浑浊物质、多酚氧化色素及硫化物异味,活性炭通过吸附胶体与致味分子,显著提升酒体清澈度与口感。

产生场景

原料杂质、发酵副产物、加工污染、储存变质

吸附目标物

色素类、异味物质、有机杂质、微生物代谢产物、重金属及农药残留

应用场景

酒类净化:白酒/威士忌、啤酒/葡萄酒、黄酒/米酒

饮料脱色:果汁/茶饮、糖浆/甜味剂、功能饮料

治理工艺

吸附法:固定床吸附、粉末投加

组合工艺:生物活性炭、臭氧-活性炭联用

Clarkson 产品系列

CKC-BV-TCLR, CKC-BV-CHTC

案例

柠檬酸饮料脱色中饮料因柠檬酸混浊发黄,经投加果壳活性炭快速吸附色素,脱色时间缩短30%,饮料清澈透明。

食用油脱色与精练

活性炭在食用油脱色与精炼中通过吸附色素、有害物质及异味,显著提升油脂安全性和感官品质。其应用需结合具体场景选择工艺,并通过组合技术优化脱色效率。

产生场景

原料杂质、加工污染、高温氧化产物、储存变质

吸附目标物

色素类、有害有机物、重金属及农药残留、异味物质

应用场景

大豆油精炼、废食用油再生、功能性油脂提纯、菜籽油脱色

治理工艺

吸附法:粉末活性炭投加、颗粒活性炭固定床

组合工艺:活性炭-活性白土联用、高温吸附

Clarkson 产品系列

CKC-EO-TCLR, CKC-EO-CHTC

案例

某油脂厂采用活性炭-白土脱色

背景:采用传统白土脱色,成本高且产生大量废渣

方案:采用颗粒活性炭(用量7%,粒度100~300目),替代部分白土工艺,

效果:脱色率提升至60%,减少白土用量30%,油脂稳定性增强。

味精(谷氨酸钠)脱色纯化

味精发酵液中残留的焦谷氨酸、类黑素等杂质影响成品透光率,活性炭通过两段吸附工艺精准去除大分子有机物,提升产品纯度。

产生场景

发酵液杂质、中和液浑浊、金属离子污染

吸附目标物

色素类、有机杂质、金属离子、异味物质

应用场景

发酵液预处理、中和液脱色、结晶前精制

治理工艺

吸附法:粉末活性炭投加、颗粒活性炭固定床

组合工艺:活性炭-离子交换树脂联用、膜过滤-活性炭联用

Clarkson 产品系列

CKC-MG-TCLR, CKC-MG-CHTC

案例

某味精厂采用活性炭脱色

背景:传统脱色工艺使用白土,脱色率仅50%,且产生大量废渣。

方案:用木质粉末活性炭(添加量2%,温度60℃,pH 7.0),结合离心过滤。效果:脱色率提升至85%,谷氨酸钠透光率(425nm)达98%,废渣量减少40%。

甘油脱色与精制

粗甘油(生物柴油副产品)中残留的醛酮类色素及金属离子影响医药级甘油品质,活性炭通过深度吸附降低灰分与色度,确保成品透光率≥97%。

产生场景

甘油蒸馏前的预处理或成品精制阶段

原料杂质:生物柴油副产甘油、皂化法甘油

加工污染:中和与蒸馏残留

储存变质

吸附目标物

色素类、有机杂质、无机杂质、异味物质

应用场景

粗甘油预处理、中和液脱色、蒸馏后精制

治理工艺

吸附法:粉末活性炭投加、颗粒活性炭固定床

组合工艺:离子交换-活性炭联用、膜过滤-活性炭联用

Clarkson 产品系列

CKC-GC-TCLR, CKC-GC-CHTC

案例

活性炭用于甘油脱色和提纯

背景:某生物柴油厂副产粗甘油(含皂化物8%、色素深),无法直接销售。

方案:投加木质粉末活性炭(添加量3%,温度70℃),结合离心分离皂化物。

效果:脱色率85%,甘油纯度提升至88%,达到工业级标准。

糖液脱色与纯化

糖液脱色是制糖工艺的核心环节,直接影响产品色泽与市场竞争力。活性炭通过吸附焦糖色素及胶体杂质,确保糖液清澈透明,满足高端食品加工需求。

产生场景

原料杂质:甘蔗汁/甜菜汁、糖蜜

加工污染:中和与澄清、蒸发结晶

吸附目标物

色素类、胶体与悬浮物、有机杂质、无机杂质

应用场景

甘蔗汁/甜菜汁预处理、糖浆脱色、精制糖生产、糖蜜回收利用

治理工艺

吸附法:粉末活性炭投加、颗粒活性炭固定床

组合工艺:离子交换-活性炭联用、膜过滤-活性炭联用

Clarkson 产品系列

CKC-SR-TCLR, CKC-SR-CHTC

案例

活性炭用于糖脱色和纯化

背景:某甘蔗糖厂糖浆色值超标(80 IU),无法达到一级白砂糖标准(≤45 IU)。

解决方案:投加椰壳粉末活性炭(添加量1.2%,温度80℃,pH 6.5),结合板框过滤。

效果:色值降至35 IU,糖品透光率提升至98%。