描述

锂电电池制造

活性炭在锂电池制造中实现了高效低成本的污染控制,助力行业绿色化污染升级。

产生场景

电极制备、电解液注液、电池组装与焊接、老化与测试

吸附目标物

有机污染物、酸性气体、颗粒物、异味物质

应用场景

涂布车间、注液车间、焊接车间、电池测试区、厂区废气总排口

治理工艺

固定床吸附塔、活性炭浓缩+催化燃烧、移动式吸附装置

Clarkson产品系列

CKC-BM-TCLR, CKC-BM-CHTC

案例

某锂电池厂涂布工序NMP废气治理

问题:涂布烘干工序NMP挥发量达2000 mg/m³,远超排放标准(≤80 mg/m³)。

方案:采用“沸石转轮浓缩+活性炭吸附”组合工艺,废气经浓缩后进入活性炭吸附塔。

效果:排放浓度降至20 mg/m³以下,活性炭更换周期延长至6个月,运行成本降低30%。

锂电池回收与再利用

活性炭在锂电回收中通过吸附-再生循环,实现了资源回收与污染控制的双重目标,其核心价值包括:高效选择性、成本优势和环保合规。

产生场景

浸出液污染、电解液挥发、废气排放、废水处理

吸附目标物

重金属离子、有机污染物、氟化物与酸性气体、颗粒物与粉尘

应用场景

浸出液净化、电解液回收、废气处理、废水深度处理

治理工艺

固定床吸附、粉末活性炭(PAC)投加、吸附-膜分离、化学沉淀-活性炭、热解-活性炭净化

Clarkson 产品系列

CKC-LR-TCLR, CKC-LR-CHTC

案例

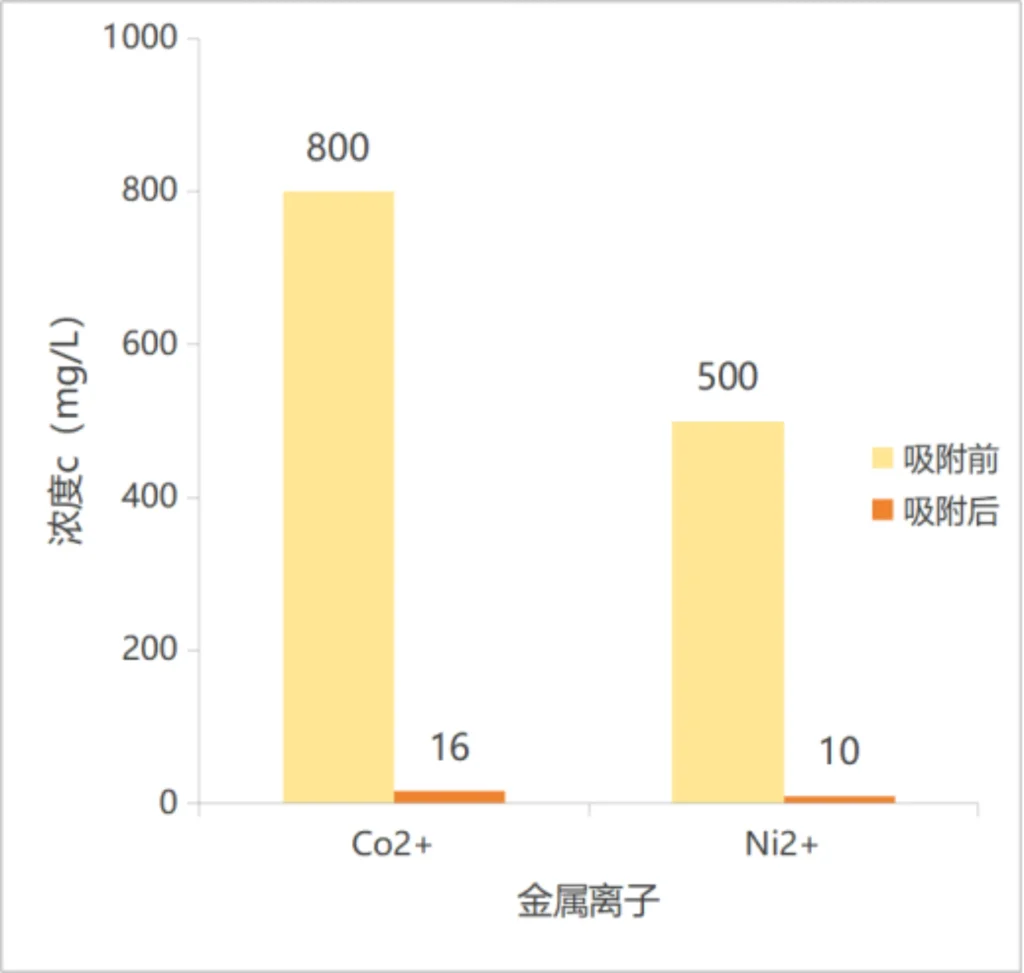

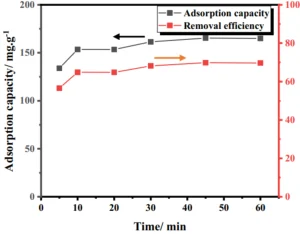

问题:浸出液含Co²⁺800 mg/L、Ni²⁺500 mg/L,传统沉淀法效率低。

方案:采用改性活性炭固定床吸附,pH调节至5~6。

效果:Co²⁺、Ni²⁺吸附率>98%,金属回收纯度达99.5%。