描述

光伏行业气相专用炭

产生场景

扩散工艺、丝网印刷、硅片切割、制绒工艺、酸洗、蚀刻工艺、扩散炉尾气等

吸附目标物

光伏行业常见生产废气,如酸性气体、粉尘与金属蒸气、氨、氟化颗粒物(>0.1 μm)、臭氧、非甲烷总烃(NMHC)等

应用场景

活性炭吸附塔、复合净化系统、洁净室空气净化

治理工艺

多级活性炭吸附、吸附脱附+催化燃烧、化学改性/催化深度处理、蒸汽/氮气吸脱附、RTO应急等。

Clarkson 产品系列

CKC-PV-TCLR-G, CKC-PV-CHTC-G

案例

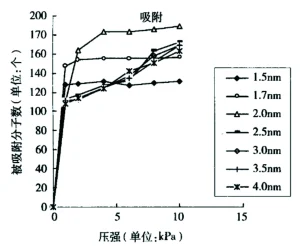

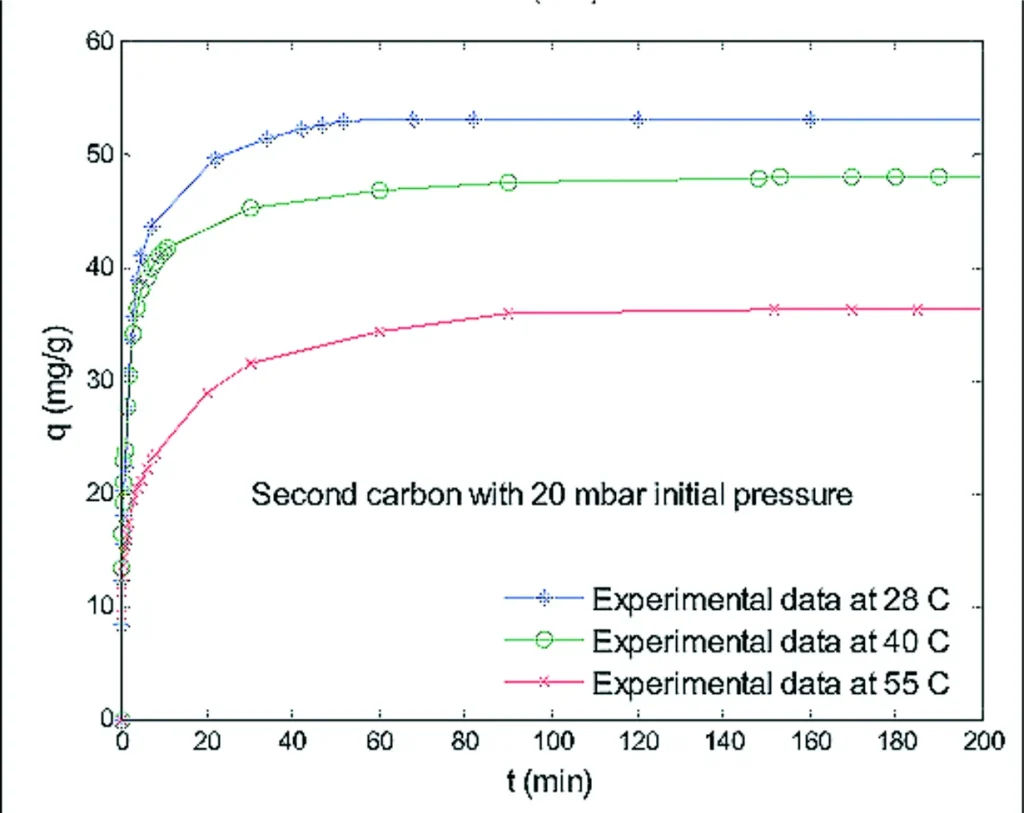

浙江某光伏基地采用两级活性炭吸附,VOCs去除率>98%,HF排放浓度<2 mg/m³(国标限值6 mg/m³)。在压力为20mbar,温度28、40和55℃的温度下,接触时间对活性炭吸附HF气体的影响。

光伏行业液相专用炭

活性炭在光伏行业水处理中因其高效的吸附能力和经济性,被广泛应用于去除废水中的有机物、重金属离子及微量污染物,尤其在处理复杂成分的工业废水时表现突出。

产生场景

切割、酸洗、蚀刻、电镀

吸附目标物

酸碱物质、有机溶剂、金属离子、悬浮颗粒等。

治理工艺

常规吸附、化学改性/催化深度处理、活性炭吸附+化学沉淀等。

Clarkson 产品系列

CKC-PV-TCLR-L, CKC-PV-CHTC-L

案例

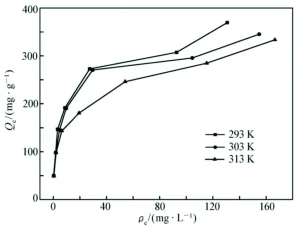

大型光伏企业废水处理厂

背景:废水含硅粉、切割液残留、重金属离子及高浓度COD(pH波动2~11)。

工艺:预处理→活性炭吸附→深度处理

效果:COD从100,000 mg/L降至500 mg/L以下,回用水率达70%。

生产环境洁净度控制

产生场景

车间空气净化

目标污染物

异丙醇、丙酮、甲苯、二甲苯、磷化氢、氟化氢、氯气、氨气、臭氧、硅烷等。

治理工艺

活性炭复合过滤、沸石转轮+活性炭联用、活性炭吸附+催化燃烧、碱性洗涤+活性炭吸附等。

Clarkson 产品系列

CKC-SCR-TCLR, CKC-SCR-CHTC

案例

硅片清洗车间VOCs治理

背景:异丙醇清洗剂挥发导致车间VOCs浓度超50 mg/m³(国标≤30 mg/m³)。

治理方案:

吸附浓缩:沸石转轮+活性炭联用,VOCs浓缩10-20倍。

脱附再生:150℃蒸汽脱附,活性炭循环使用。

效果:VOCs排放浓度<10 mg/m³。