描述

橡胶轮胎行业气相专用炭

活性炭在橡胶轮胎行业环保治理中主要用于吸附污染物和降低排放。生产环节中,它可捕获混炼、硫化产生的VOCs和硫化氢,减少废气污染;废轮胎热解时,吸附裂解气体中的硫化物和焦油,降低二次污染;还能净化含橡胶助剂的废水,去除难降解有机物。此外,活性炭添加于再生胶中可抑制脱硫异味,助力废胎资源化。

产生场景

密炼工序、压延与挤出、硫化工艺、胶料存储与转运、废胶处理

吸附目标物

苯、甲苯、二氧化硫、硫化氢(H2S)、醇类、氨气(NH3)、多环芳烃等。

应用场景

车间废气处理、轮胎异味控制、仓储环境净化

治理工艺

固定床吸附塔、活性炭纤维滤网、催化氧化燃烧

Clarkson 产品系列

CKC-RT-TCLR-G, CKC-RT-CHTC-G

案例

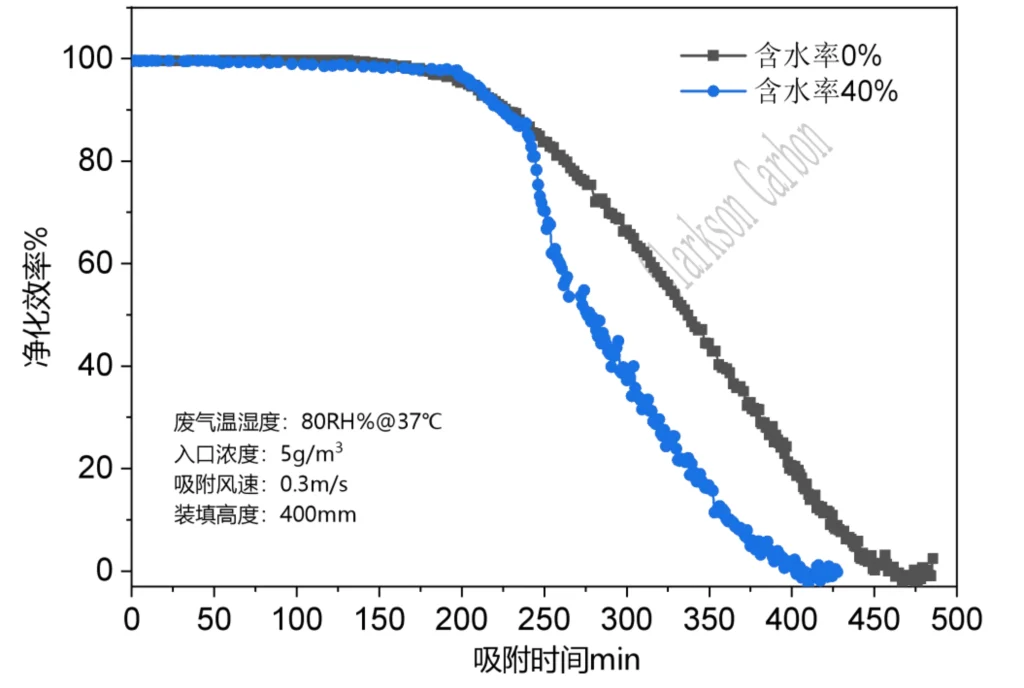

某轮胎厂在生产过程中,因使用含乙醇的溶剂导致废气中醇类浓度升高(检测值约300-500 mg/m³),需处理至地方排放标准(≤50 mg/m³)。采用活性炭吸附系统进行治理。

工艺流程:废气收集 → 预处理(除湿+过滤)→ 活性炭吸附 → 达标排放

处理效果:- 出口浓度:稳定<30 mg/m³,去除率>90%。

橡胶轮胎行业液相专用炭

活性炭在橡胶轮胎行业液相环保治理中,主要用于处理生产废水。其通过吸附废水中残留的橡胶助剂(如防老剂、促进剂)、硫化物及难降解有机物(如苯系物、邻苯二甲酸酯),有效降低COD和毒性。采用粉末活性炭直接投加或颗粒活性炭过滤柱,实现深度净化,确保废水达标排放(如COD≤100mg/L)。

产生场景

混炼工序废水、硫化工艺废水、设备润滑与冷却废水、成型工序废胶浆

吸附目标物

苯系物、硫化物、有机溶剂、 增塑剂、 重金属离子、胶体污染物

应用场景

吸附有机溶剂及VOCs、脱除含油废水中的乳化油、硫化物及重金属去除

治理工艺

固定床吸附、活性炭+离子交换树脂、化学改性/催化深度处理、氮气/水蒸气吸脱附

Clarkson 产品系列

CKC-RT-TCLR-L, CKC-RT-CHTC-L

案例

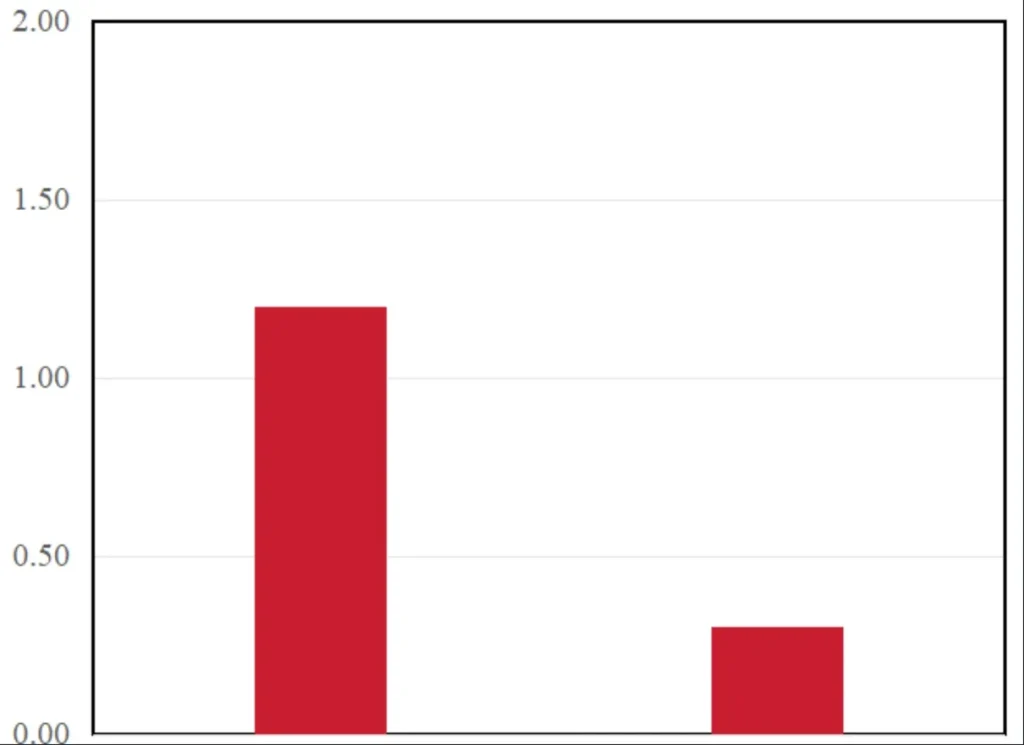

湖北某轮胎厂热解油净化:活性炭吸附后,热解油硫含量从1.2%降至0.3%,达到燃料油标准。