描述

垃圾焚烧尾气处理

垃圾焚烧过程中产生的烟气含有多种有毒有害气体,直接排放会严重威胁环境和人体健康。活性炭凭借其高比表面积和强吸附能力,成为烟气净化系统的核心材料,助力实现高效减排。

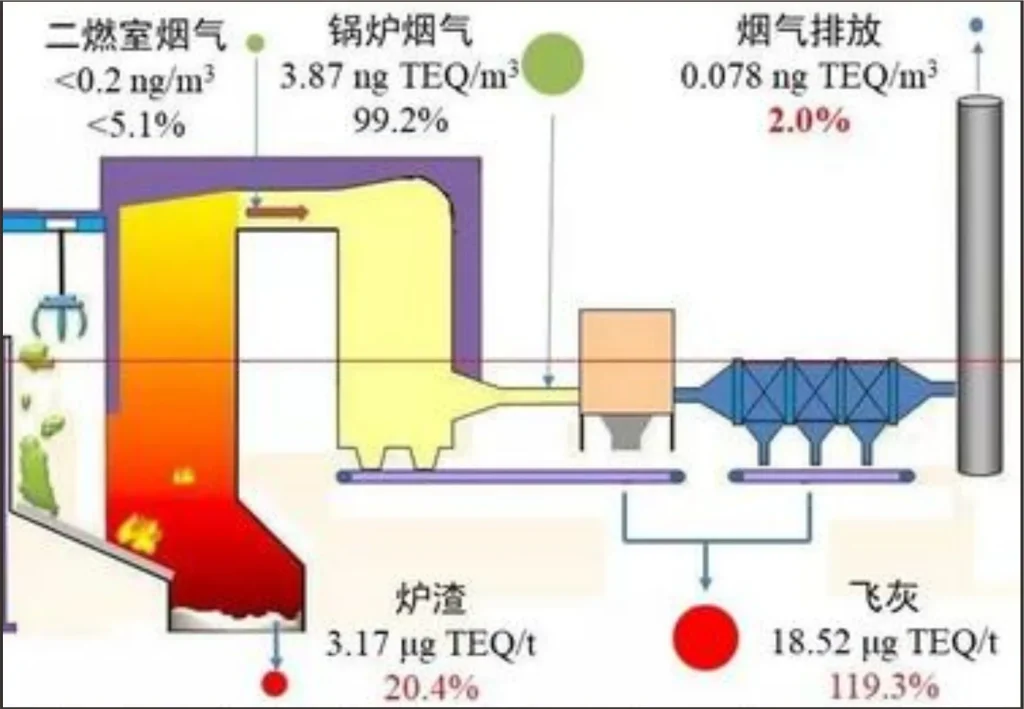

产生场景

二燃室、锅炉、炉渣等。

吸附目标物

二噁英类物质、酸性气体、挥发性有机物(VOCs)、重金属蒸气

应用场景

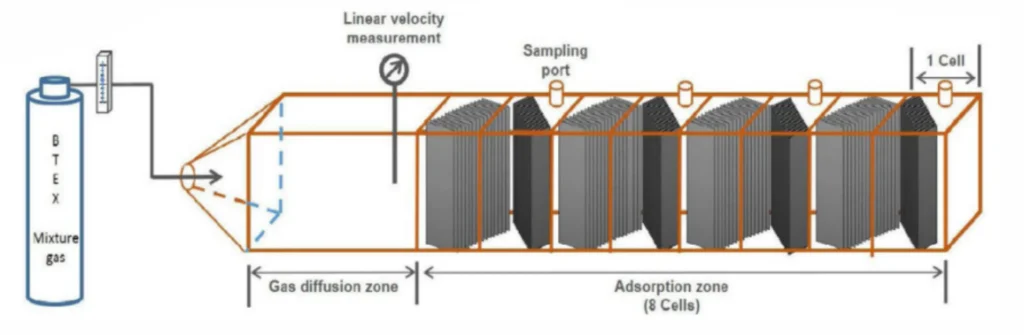

烟道喷射系统:粉末活性炭(PAC)直接喷射、协同脱酸

活性炭滤床(固定床):颗粒活性炭(GAC)滤层、组合工艺

治理工艺

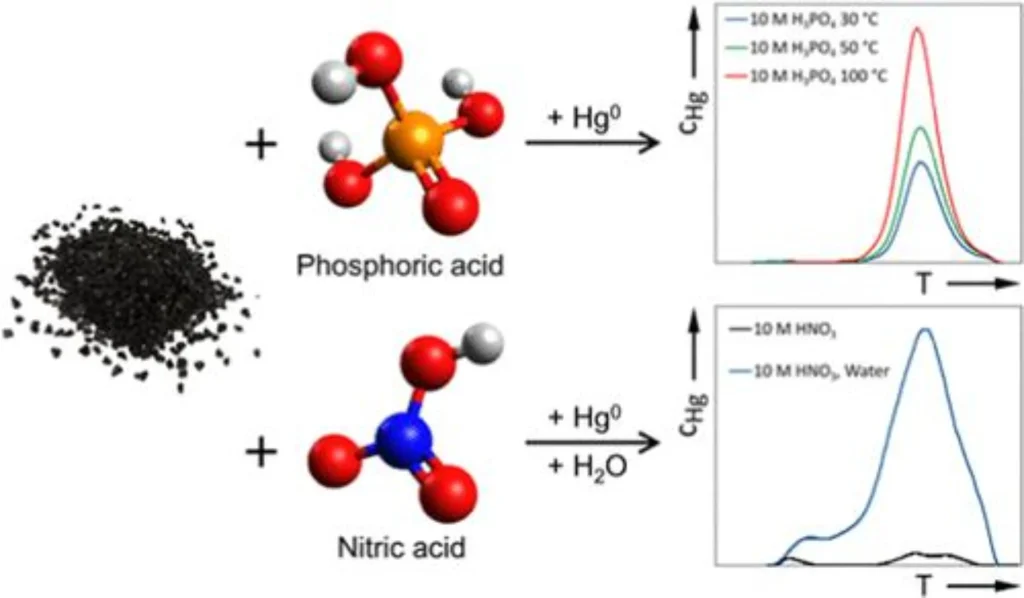

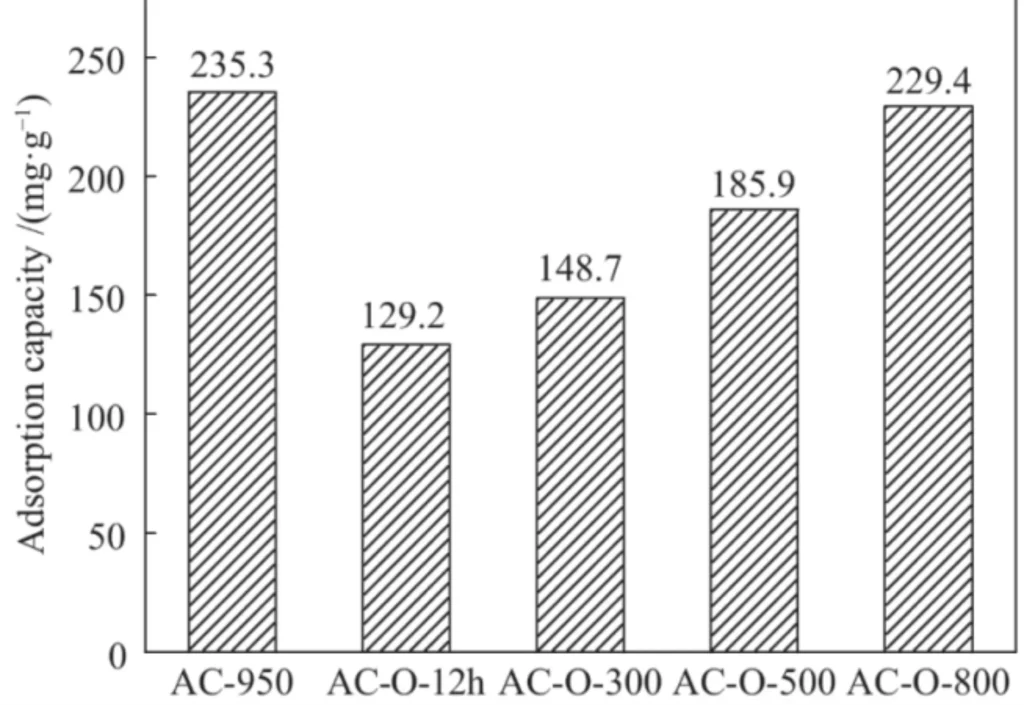

干法喷射、固定床吸附、改性活性炭技术

Clarkson产品系列

CKC-WI-TCLR, CKC-WI-CHTC

案例

上海某垃圾焚烧厂原尾气二噁英浓度1.5 ng TEQ/Nm³,采用PAC喷射(投加量100 mg/Nm³)+ GAC滤床(厚度1.2 m),二噁英降至0.03 ng TEQ/Nm³,Hg浓度从50 μg/Nm³降至2 μg/Nm³。

危废填埋场 废气处理

危废填埋场在长期堆存过程中会释放含硫、含氮化合物、挥发性有机物(VOCs)及恶臭气体,具有成分复杂、浓度波动大、毒性显著等特点。活性炭凭借其广谱吸附能力与表面化学改性潜力,成为填埋场废气净化的高效解决方案,可同步解决污染物去除与异味控制难题。

产生场景

填埋作业区、渗滤液收集池、封场后持续排放、事故泄漏

吸附目标物

恶臭物质、有毒VOCs、温室气体、重金属蒸气

应用场景

填埋作业区气体收集系统:移动式活性炭吸附装置、负压集气+活性炭塔

渗滤液处理设施:密闭池体废气处理

封场后气体管理:长期监测与吸附

应急处理:泄漏事故吸附

治理工艺

活性炭吸附塔、活性炭-生物滤池联用、改性活性炭

Clarkson 产品系列

CKC-HW-TCLR, CKC-HW-CHTC

案例

江苏某垃圾焚烧厂内含汞污泥填埋场封场后汞蒸气逸散(浓度0.1 mg/m³),超限值10倍,使用硫改性活性炭滤罐(Hg吸附容量80 mg/g),结合实时监测系统,汞浓度稳定<0.01 mg/m³。