描述

汽车整车喷涂车间

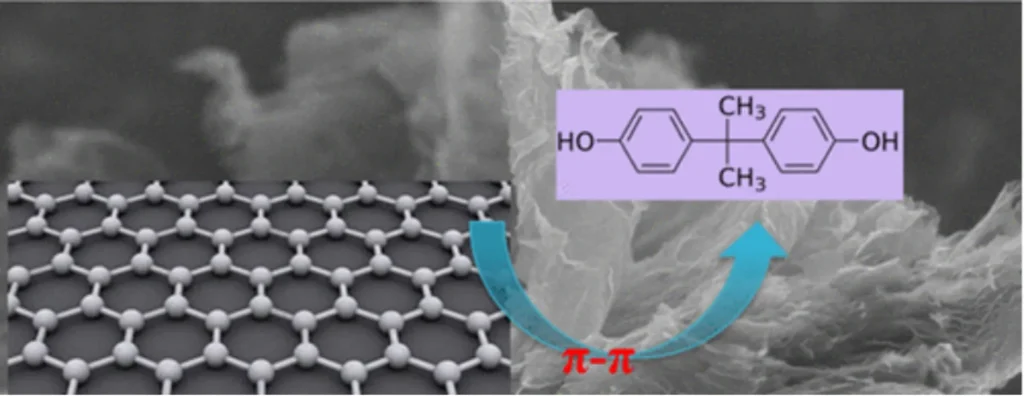

喷涂行业使用大量有机溶剂和染料,这类挥发性污染物分子通常为极性分子。将活性炭表面以富电子的极性基团修饰负载后,对于偶极矩较大的污染物分子,具有高效的特异性捕集能力。喷涂行业的废液含有大量的重金属离子,创造性地以羧酸或烷氧基负载后的活性炭,对于废水中的金属离子具有选择性配位络合能力。

产生场景

喷漆作业、烘干环节、调漆与设备清洗、漆雾颗粒携带

吸附目标物

苯系物、酯类与酮类、醇类与醛类、颗粒物携带的VOCs

应用场景

喷漆房废气处理、烘干室尾气净化、调漆间局部排风、车间整体换气系统

治理工艺

多级活性炭吸附、活性炭吸脱附+催化燃烧(RCO)、沸石转轮浓缩+活性炭保障、湿式除尘+活性炭吸附、活性炭蒸汽/氮气吸脱附

Clarkson产品系列

CKC-CS-TCLR, CKC-CS-CHTC

案例

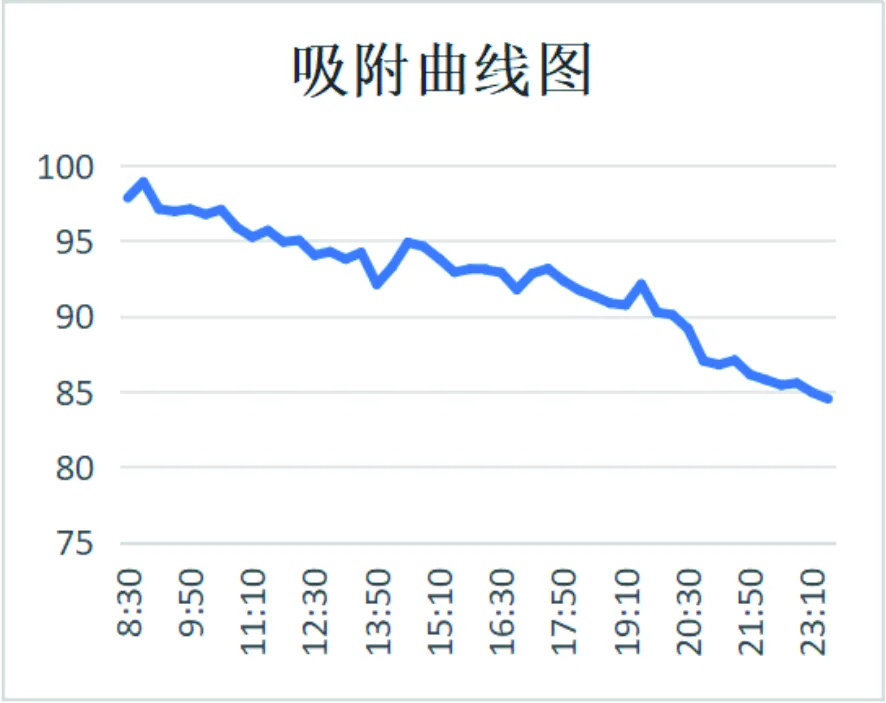

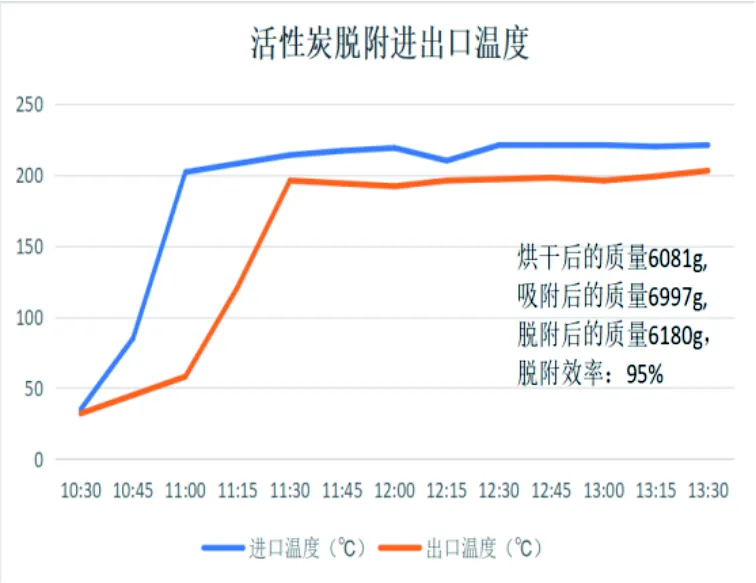

某合资车企喷涂车间VOCs治理

背景:喷漆废气非甲烷总烃浓度800 mg/m³,超《大气污染物综合排放标准》(GB 16297-1996)限值(120 mg/m³)。

解决方案:采用活性炭+RCO,处理风量20万m³/h。

效果:排放浓度降至15 mg/m³。

航空器特种涂料喷涂

活性炭在航空特种涂料喷涂车间中,通过功能化改性与工艺创新,有效应对高毒性、多组分污染物的治理难题。未来随着航空绿色制造标准升级,活性炭技术将向精准吸附、智能再生方向深度演进,成为航空业可持续发展的重要技术支点。

产生场景

机身喷涂、烘干固化、调漆与清洗、复合材料涂装

吸附目标物

VOCs、重金属、颗粒物、异味物质应用

应用场景

主喷涂线排风系统、烘干炉尾气治理、调漆间负压抽排、复合材料涂装区、维修机库

治理工艺

多级活性炭吸脱附、活性炭蒸汽/氮气吸脱附、沸石转轮+活性炭、活性炭催化氧化、活性炭吸脱附+催化燃烧

Clarkson 产品系列

CKC-AS-TCLR, CKC-AS-CHTC

案例

某飞机制造商环氧涂料喷涂线改造

问题:环氧底漆喷涂释放双酚A(浓度达15 ppm),远超欧盟限值(≤0.01 ppm)。

方案:采用改性活性炭吸附塔,结合紫外光离子化检测仪实时监控。

效果:双酚A去除率>99.5%,排放浓度稳定<0.005 ppm。