描述

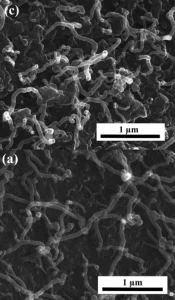

印染废水专用炭

印染废水成分复杂,不仅对当地生态有严重危害,还会导致水体富氧化,出现大规模污染现象,危害人类健康,影响水体生态平衡和生物族群稳定性。20世纪后期至今,随着技术的成熟与普及,活性炭在印染废水处理中成为主流技术之一,用于脱色、去除COD(化学需氧量)及有毒物质。

产生场景

退浆、染色、印花、后处理等.

吸附目标物

染料类、有机污染物、重金属离子、色度与悬浮物等

应用场景

深度废水处理、应急处理、回用水处理、工艺优化

治理工艺

活性炭常规吸附、化学改性/催化深度处理、高级氧化工艺(如臭氧-活性炭联用)等

Clarkson产品系列

CKC-PD-TCLR-G, CKC-PD-CHTC-G

案例

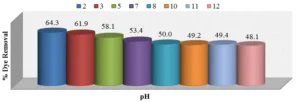

染料废水脱色与COD去除(江苏某大型印染厂)

工艺设计:采用“混凝沉淀+活性炭吸附”组合工艺。

废水特点:高色度(约5000 Pt-Co)、COD(化学需氧量)高达2000 mg/L。

活性炭类型:粉末活性炭(PAC)投加量0.5-1.5 g/L。

处理效果:

色度去除率:95%以上(吸附后色度<100 Pt-Co)。

COD去除率:80%-90%(降至200-400 mg/L)。

优势:快速吸附偶氮染料、活性染料等难降解有机物,弥补生化处理的不足。

印染废气专用炭

印染企业在生产的工序中会产生大量的废气,主要成分为颗粒物、油烟、甲醛、多苯类、芳香烃类VOCs等。如果不妥善处理达标排放,就会对环境造成较大影响,而且影响周围居民身体健康。

产生场景

烘干、定型、印花等工艺

吸附目标物

甲苯、丁酮、丙酮、二氯甲烷、二氯乙烷、乙酸乙酯、DMAC硫化氢、硫醇等(VOCs)

应用场景

烘干废气处理、 定型机尾气净化、 车间空气净化

治理工艺

活性炭多级吸附、溶剂回收、吸附脱附+催化燃烧、化学改性/催化深度处理等

Clarkson 产品系列

CKC-PD-TCLR-L, CKC-PD-CHTC-L

案例

纺织涂层企业DMF&甲苯串联回收工艺

企业背景:吴江某涂层企业,采用干法直接涂层生产工艺,产量约为20万m/t,DMF用量500kg/d,甲苯2400kg/d。

处理效果:

污染物去除率:DMF、甲苯去除效率达98%以上,DMF、甲苯排放达到相应排放标准要求。

经济效益:正常运行情况下每天可回收DMF水溶液2.38t,甲苯2.28t,每天节约成本约1万元,扣除水、电、蒸汽消耗可实现每天1万元以上的收益。

环境效益:消耗的工艺水少,每天只需15t循环吸收液补水,DMF吸收液可循环使用,无二次污染。